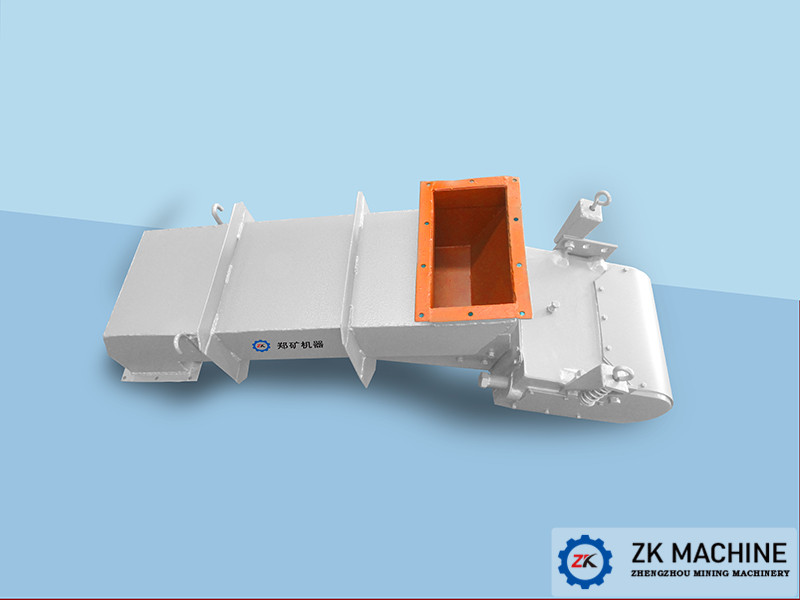

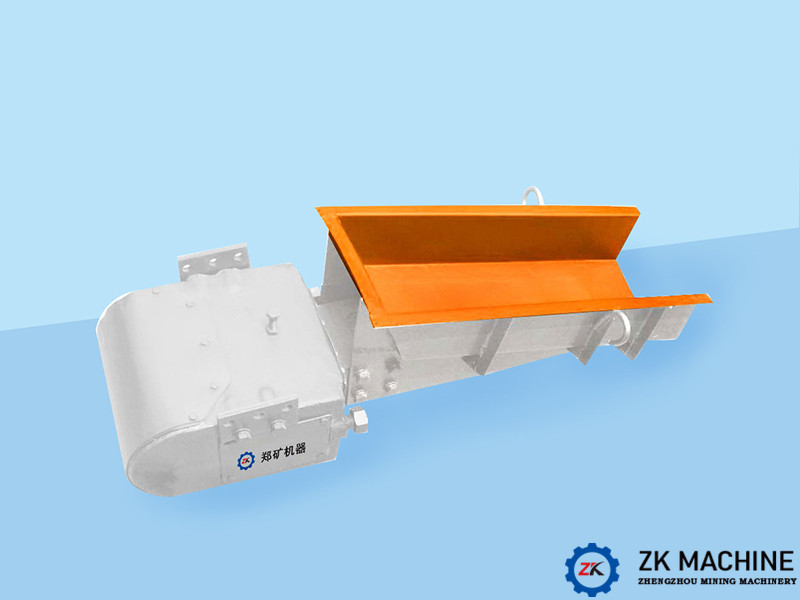

Brief Introduction Of Electromagnetic Vibrating Feeder

Date:2020-06-09 Source:zk corp Views:

GZ series electromagnetic vibrating feeder is widely used in various industries such as mining, metallurgy, coal, building materials, light industry, chemical industry, electric power, machinery, food, etc., Lump, granular and powdery materials are uniformly and continuously or quantitatively fed from the storage bin or funnel to the receiving device. For example, feeding belt conveyors, bucket elevators, screening equipment, crushing equipment, mixing equipment, grinding equipment, etc., feeding to crushers, pulverizer, etc., as well as for automatic batching, quantitative packaging, etc. And can be used in the process of automatic control to realize the automation of the production process.

Electromagnetic vibrating feeder is a new type of feeding equipment. Compared with other feeding equipment, it has the following characteristics:

1. Small size, light weight, simple structure, small space occupation, low noise, low energy consumption, easy installation, no rotating parts without lubrication, simple operation, convenient maintenance, low operating cost and low maintenance cost;

2. Due to the use of the resonance principle of mechanical vibration, the double mass works in a low critical near resonance state, so the power is small, the energy efficiency is high, the power consumption is low, and the use cost is saved;

3. The amplitude is large, which overcomes the disadvantage of difficult conveying of powdery and viscous materials.

4. Since the material flow can be changed and opened and closed instantaneously, the feeding amount has high precision, the position of the feeding point is well controlled, and the precision is high;

5. The control equipment of this series of feeders adopts thyristor half-wave rectifier circuit, so in the process of use, it is possible to adjust the feeding amount conveniently and steplessly by adjusting the opening angle of the thyristor, and can realize the production process of centralized control and automatic control;

6. Since the material in the feed trough is continuously thrown up during the feeding process and jumps forward according to the parabolic trajectory, the feed trough is less worn and has a long service life;

7. The material tank made of alloy steel plate is suitable for conveying high temperature, severely worn and corrosive materials, and the material tank can be replaced easily without affecting the normal production and use;

8. The adjustment of the working point is realized by the automatic tracking of the electric control system, which simplifies the debugging and maintenance work. An amplitude indicator is provided on the panel of the electric control box, which is convenient for remote control and centralized control.

9. Due to the use of frequency reduction technology, compared with the traditional electromagnetic vibrating feeder, the noise reduction effect of this series of electromagnetic vibrating feeder is obvious.

10. Not suitable for occasions with explosion-proof requirements.

The above is the introduction of the electromagnetic vibrating feeder. If you want to know more equipment information, please consult the customer service staff of China ZK Corp. ZK Corp is a professional mining machinery manufacturer with rich technical accumulation and project experience. We sincerely invite you to visit our factory on site!

- Next Page: Introduction of Corrugated Belt Conveyor

- Previous: Application of Bag Filter