Cement Clinker Grinding Plant

Capacity:50 t/d-1500 t/d

Main Materials:Clinker, Gypsum, Additives

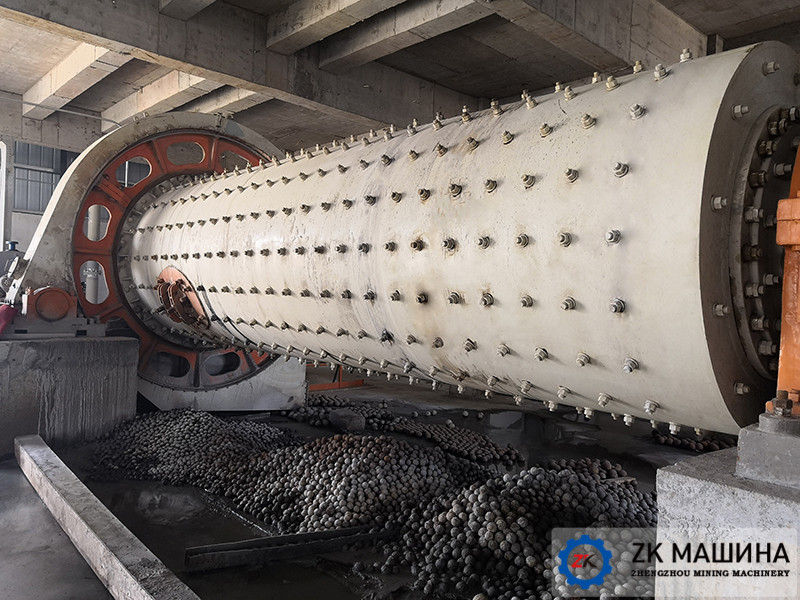

Main Equipment:Vertical Cement Mill, Cement Ball Mill, Cement Roller Press etc

Introduction

Cement clinker grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement production. The new-type cement grinding units adopt pre-grinding technology. The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce the energy consumption.

The cement grinding machine includes cement dryer, cement ball mill, cement roller press, powder selecting machine, conveyor and other cement equipment. We can provide scheme design for free according to the requirements of users, and offer appropriate equipment to ensure smooth production with less investment and high profit.

Our Advantage

1. High grinding efficiency

For the structure, of the cement mill, weadopts the advanced obstructing equipment for internal powder, add theactivated device to the fine grinding chamber, and there is the special grateplate at the end of the cement mill, which can reduce the size of the grindingmedium, greatly improve the grinding efficiency, and achieve the purpose ofhigh output and low energy consumption.

2. Energy saving and environmental protection

The cement grinding unit has advantages of simple structure,strong controllability, and easy to operate or maintain. The dischargeconcentration is less than 50mg/Nm3, lower than the discharge standard, andprotect the environment of the production site effectively.

3. Good quality of finished products

The production process overcomes the disadvantages of traditionalequipment. The fineness of product is easy to be adjusted, apply for differentrequirement of fineness. The equipment also has advantages of large heatdissipation area and low temperature inside mill. The finished product ofnew-type cement grinding unit has high quality and large capacity.

4. High output, large handling capacity

Compared to other production process, with samefeeding size and other working conditions, our cement grinding unit canincrease capacity by 30%, and the energy consumption can be reduced by 15%.

Production Technology

1. Batching: The shipping clinker is discharged into the dock crane and then transported to the clinker warehouse. After unloading at the bottom of the tent warehouse, it is transported to the clinker batching warehouse. Gypsum and slag are transferred from the loader to the crusher for crushing and then hoisted into gypsum and slag storehouse respectively.

2. Weighing, mixing and feeding cake: After battering the bottom of the warehouse, it will be sent to the stable flow weighing bin of the cement mill by the belt conveyor, and an iron remover will be arranged on the conveyor. The materials are mixed and stabilized in the steady flow weighing bin, and then fed into the cement roller press uniformly and continuously in the form of a material column. After the material passes through the high pressure, the physical structure is destroyed, forms the material cake and it will be raised by the hoist feeding classifier.

3. Grading: The classifier breaks the cake and grades it, and then separates the fine powder less than 6mm from the coarse powder more than 6mm. The coarse powder is returned to the stable flow weighing bin of the cement roller press, and then extricated again, and the fine powder is fed into the cement mill. After the fly ash is measured by the reamer scale, it goes through the chute into the hoist and feeds directly into the cement mill through the chute and the feeding chute.

4.Grinding: after cement mill grinding, materials enter into the powder separator, the fine powder is sent to the cement silo by the air transmission chute and the elevator, the coarse powder back to the cement mill to continue grinding. One part of the outgoing cement is controlled by the bottom unloader of the fluidized warehouse, and then through the air conveying chute and the elevator, sent to the packaging machine room for delivery, while the other part is sent to the bulk carrier for delivery by the air conveying chute.

Configuration

| No. | Item | Unit | Closed circuit production | ||||

| 1 | Factory capacity | ×10³t/a | 100 | 160 | 250 | 350 | 500 |

| 2 | Main material usage | ||||||

| ① | Clinker | t/a | 80000 | 128000 | 200000 | 280000 | 400000 |

| ② | Gypsum | t/a | 5000 | 8000 | 12500 | 17500 | 25000 |

| ③ | Pozzolana | t/a | 15000 | 24000 | 37500 | 52500 | 75000 |

| 3 | Energy consumption | ||||||

| ① | Fresh water | t/a | 4000 | 7000 | 9000 | 12000 | 17000 |

| ② | Electrical | kWh/a | 3600000 | 5700000 | 8500000 | 1200000 | 1.7E+07 |

| 4 | Layout transportation | ||||||

| ① | Land area | ㎡ | 15000 | 18000 | 20000 | 22000 | 24000 |

| 5 | Project invest | ||||||

| ① | Production line total invest | Ten | 600 | 1000 | 1500 | 2000 | 2850 |

| thousand | |||||||

| 6 | Workers | 30 | 35 | 35 | 35 | 35 | |

| 7 | Main equipment | ||||||

| ① | Ball mill | Φ2.2×6.5m | Φ2.4×11m | Φ3×11m | Φ3.2×13m | Φ3.5×13m | |

| 14t/h | 24t/h | 35t/h | 50t/h | 70t/h | |||

| 380kW | 630kW | 1250kW | 1600kW | 2000kW | |||

| ② | Belt conveyor | B500 | B650 | B650 | B800 | B1000 | |

| ③ | Mill outlet bucket elevator | TH315 | TH400 | NE100 | NE150 | NE200 | |

| ④ | Air classifier | NHX400 | NHX600 | NHX700 | NHX800 | NHX1000 | |

| (Osepa N250) | (Osepa N500) | (Osepa N750) | (Osepa N1000) | (Osepa N1500) | |||

| ⑤ | Bag filter | PPC32-4 | PPC32-6 | PPC64-5 | PPC64-6 | PPC64-7 | |

| (PPC64-6) | (PPC96-7) | (PPC96-2×5) | (PPC96-2×6) | (PPC96-2×10) | |||

| ⑥ | Finished production bucket elevator | TH250 | TH315 | NE50 | NE100 | NE100 | |

| ⑦ | Screw conveyor | LS400 | LS400 | LS500 | - | - | |

| ⑧ | Packer | Three nozzle | Four nozzle | Six nozzle | Eight nozzle | Eight nozzle | |

| ⑨ | Belt weigher | B500×2000 | B650×2500 | B800×2500 | B800×2500 | B1000×3500 | |