A Commonly Used Screening Equipment-Rotary Drum Screen

Date:2020-06-05 Source:zk corp Views:

In the building materials industry, whether raw materials or finished materials, we often need to make a detailed distinction between them. At this time, a common material selection equipment is indispensable, that is, rotary screen. Generally speaking, the common application scenarios are as follows: the stone yard is used for the classification of large and small stones, as well as the separation of soil and stone powder; the sand yard is used for the separation of sand and stone; the coal industry is used for the separation of lump coal and pulverized coal and coal washing (a part of coal washing machine); the chemical industry and the mineral processing industry are used for the classification of large and small blocks and the separation of powder materials.

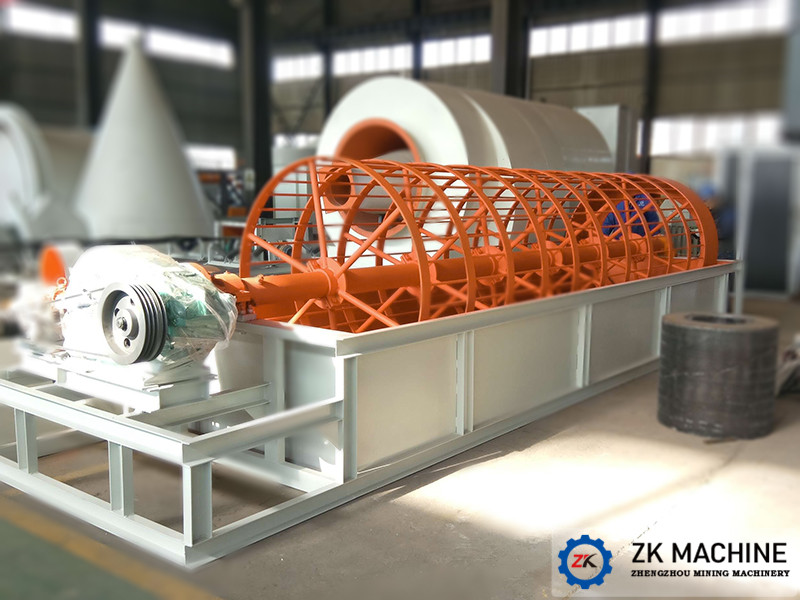

Rotary screen is a new generation of screen equipment, mainly composed of import and export, motor, reducer, frame, drum device, etc., which can be used in chemical industry, coking plant, mine, power plant, building materials, metallurgy and other industries. The roller device is installed on the frame obliquely, and the outer part is sealed by the seal isolation cover to prevent pollution.

When the rotary screen works, the motor connects the reducer with the roller device through the coupling, and drives the roller device to rotate around its axis. The rotary screen is a mechanical method, which is composed of several parallel screen bars to form a screen surface. After the materials are put into the drum device, due to the inclination and rotation of the drum device, the materials are turned and rolled. The materials are screened out one by one through the screens of different mesh purposes, and the materials stuck in the screen holes can also be ejected to prevent blocking.

Maybe we often hear the names of shaftless rotary screen and shaft rotary screen. What's the difference between them? Let's take you to know it today:

First, of course, it's a structural difference, whether it has a central axis or not;

Second, the materials are different. The shaft type is suitable for the separation of large and small blocks of materials in the ore dressing industry, while the shaft type is viscous and wet materials. The shaft rotary screen is mainly used for the input separation of large and small pieces of materials in stone plant, sandstone plant and mineral processing industry. The shaftless rotary screen is mainly used for the classification of belt and winding materials. It is used for the classification of refractories, coal, fertilizers, stones in the sand field, and the screening of coal, coke, lime, placer gold and other sticky wet materials, so as to make the product structure more uniform and meet the production needs.

Third, the transmission mode is different. The movement mode of the shaft rotary screen is that the driving device is connected with the coupling. Driven by the motor, the roller rotates around its axis.

There are three ways of transmission: chain drive, gear drive and idler drive.

①The movement mode of the shaftless rotary screen of the chain is that the motor drives the chain, the front end of the roller has gears, and the chain drives the gears of the roller to rotate.

②The movement mode of the gear shaftless rotary screen is that the front end of the roller is equipped with a big gear, and the motor drives the small gear. The small gear and the big gear are engaged together, and the drum is driven to rotate by the torsional force of the gear.

③The movement mode of rotary screen without shaft is that the roller is placed on four or more rollers, and the roller is driven to rotate by the motor. Under the action of friction, the roller is driven to rotate by the roller.

Fourth, the capacity is different. The capacity of shaftless rotary screen is 20% higher than that of shaft rotary screen.