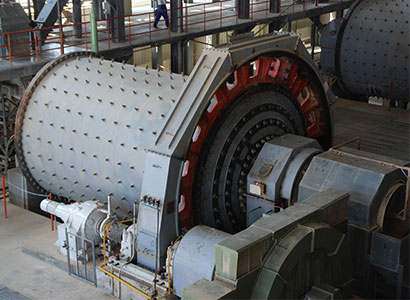

Ceramic ball mill is also called (Intermittent ball mill/Batch ball mill). Ceramic ball mill can be used to grind feldspar, quartz, clay, silica and other hard brittle materials. It is widely applied in industrial production of high fine grinding materials. Ceramic ball mill grinding has dry and wet ways, of which the dry grinding can produce ultra-fine powder with the fineness of 1000-16000 mesh.

Working principle of Ceramic Ball Mill:

The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material.

After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding.