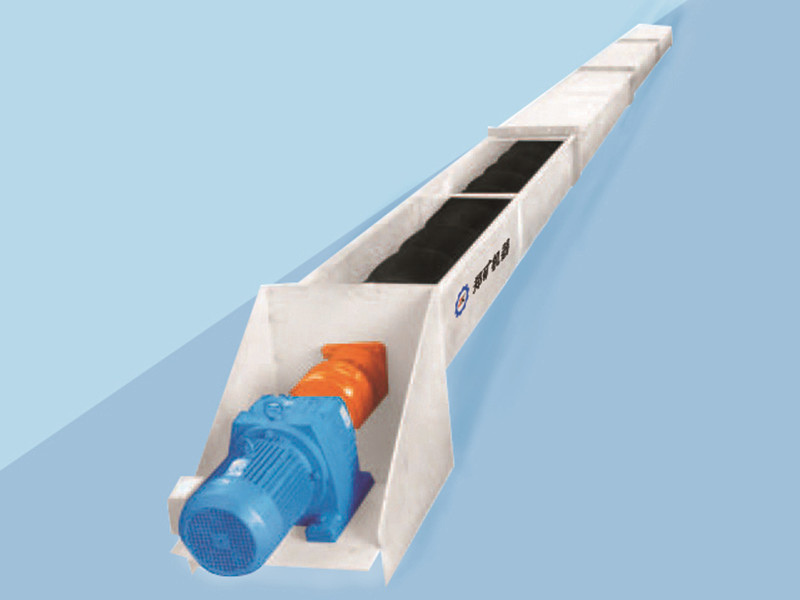

Screw conveyor has features of compact structure, small cross-sectional area, ligh weight, good sealing, high efficiency, flexible arrangement. It is convenient to assemble, dismantle, move and safety operation. It is suitable to convey all kinds of powdery, granular bulk materials, such as clay powder, coal, cement, sand, small lump coal, gravel, scrap iron etc. But not suitable for sticky agglomerate, perishable materials. Screw conveyor has horizontal and inclined arrangement. It can work with other conveying device to complete the concentrated transportation, distribution, agitation, mixing, dehydration, dosing, unload, stacking operation etc.

Application of Screw Conveyor

Screw conveyor generally used for continuity conveying bulk materials in short distance at horizontal or slightly oblique (angle β≤15 °) direction. It can mix and stir the material during conveying. The working environment is -20 ~ 50 ℃, and the material should be less than 200 ℃. Its design and fabrication meet the professional standards in JB/T7679-2008-"screw conveyor". The hanging bearing adopts the two structures of rolling and sliding interchangeable. It has low resistance, strong sealing and good wear resistance.

Types of Screw Conveyor

.jpg)