How to Adjust The Width of The Discharge Port of Jaw Crusher For Stone Breaking

Date:2016-09-27 Source:zk corp Views:

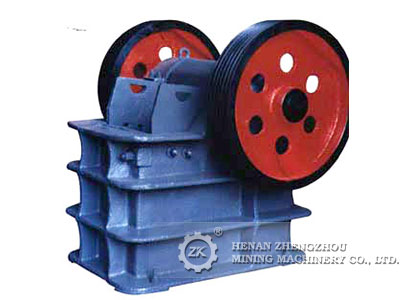

Jaw crusher for stone breaking, also known as the tiger mouth, which crushing cavity composed of mobile jaw and static jaw simulates movement of animal jaw to complete the crushing operation. Because that the structure of the jaw crusher for stone breaking has the advantages of simple and convenient operation, work reliability, convenient maintenance, so it has been welcomed in mining industry. Jaw crusher for stone breaking liner can continue to be subject to wear and tear of by the ore, which will make the discharge port be slowly increasing. The width of the discharge port will directly affect the production efficiency of jaw crusher, and the wear of the broken plate. Therefore, it is very necessary to adjust the width of the discharge port of the jaw crusher for stone breaking in time.

So how to operate and adjust the width of the jaw crusher for stone breaking discharge port?

1 Gasket adjustment

Add a set of equal thickness gaskets between the rear thrust plate bearing and the rear wall of the frame. The purpose is to increase and decrease the discharge of the jaw crusher by increasing or decreasing the number of gaskets. This method is very suitable for large and medium-sized jaw crusher.

2 hydraulic adjustment

The hydraulic drive device is installed at the discharging port, which is reliable and safe, and is easy to be eliminated. The connecting rod of the jaw crusher is provided with a hydraulic oil cylinder and a piston, and the upper part of the oil cylinder and the connecting rod is connected with the connecting rod of the connecting rod.

Jaw crusher for stone breaking is also one of the main mining machinery Co., Ltd., mining machinery, it is mainly composed of a machine frame, an eccentric shaft, a belt pulley, a flywheel side guard plate, a fixed jaw plate, a movable jaw plate and a discharging port adjusting device.

PE, PEX series jaw crusher for stone breaking takes motor as power, drive the eccentric shaft through the belt drive, so that the moving jaw make a reciprocating motion by a predetermined trajectory, The material in the crushing cavity which is composed of a fixed jaw plate, a movable jaw plate and a side guard plate is broken, and the finished material is discharged through the discharging port at the lower part.

Henan Zhengzhou Mining Machinery Co., Ltd (ZK). is a professional jaw crusher for stone breaking manufacturer, welcome to visit Tel: 0371-55902866.