Active Lime Production Line

Capacity:50-800(t/d)

Main Materials:Limestone

Main Equipment:vertical preheater, lime kiln, bag filter

Lime Activity:≥360mL

Introduction

|

Grade |

Chemical Composition % |

Activity |

|||||

|

CaO |

MgO |

SiO2 |

P |

S |

Burn |

ml |

|

|

≥ |

≤ |

≤ |

≥ |

||||

|

Special grade |

92 |

≤5.0 |

1.5 |

0.02 |

0.02 |

2 |

360 |

|

First class |

90 |

2 |

0.03 |

0.03 |

4 |

340 |

|

Our Advantage

1. The combustion equipment uses energy-saving burners to automatically control the air distribution volume to reduce the loss of incomplete fuel combustion.

2. Rotary kiln refractory bricks adopt light-weight insulation on the outer layer and composite bricks with refractory and wear-resistant inner layer to reduce heat dissipation from the outer skin of the rotary kiln.

3. There is a vertical preheater at the end of the rotary kiln, which makes full use of the high-temperature flue gas produced by the combustion of the rotary kiln to preheat the materials in the preheater, so that the materials are partially decomposed in the preheater.

4. A vertical cooler is installed at the head of the rotary kiln to make full use of the heat contained in the high-temperature calcined white material of the rotary kiln to preheat the secondary air to 600°C, which improves the thermal efficiency. Yaotou mining

5. The vertical cooler and the kiln hood are integrated in the design and construction, which has a small footprint and good sealing, which effectively avoids the fugitive emission of hot exhaust gas.

6. The kiln tail is environmentally friendly and dust collection is good. The cyclone dust collector and pulse bag filter are used for secondary dust removal, and the emission concentration is lower than the standard.

7. The level of automation is high. The adjustment, control and alarm of the production system are controlled by PLC in the main control room. There are few on-site operators and high labor efficiency.

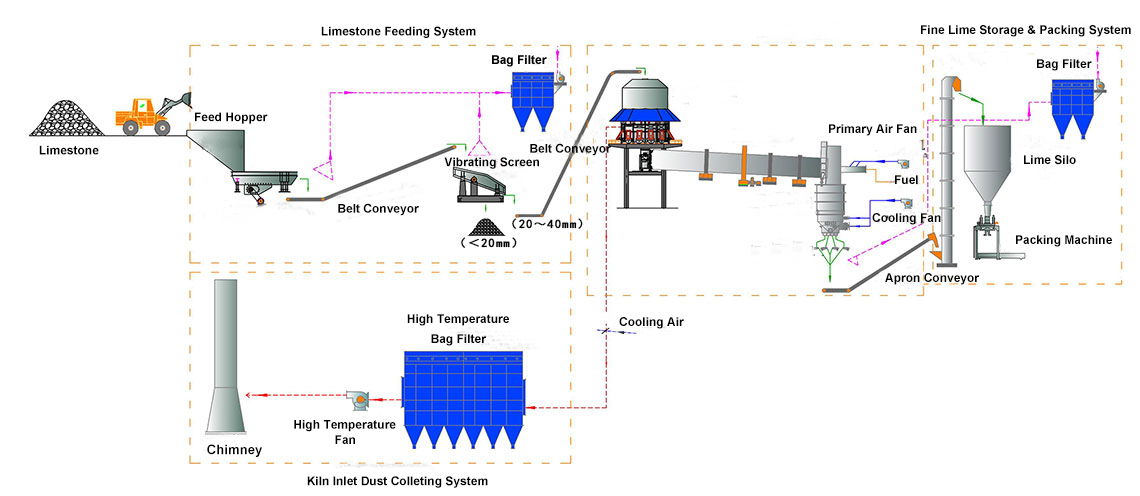

Production Technology

Configuration

|

Capacity |

200t/d |

225t/d |

250t/d |

300t/d |

400t/d |

500t/d |

600t/d |

800t/d |

|

|

Preheater |

Shape |

Hexagon |

Hexagon |

Octagon |

Octagon |

Octagon |

Decagon |

Dodecagon |

Dodecagon |

|

Qty. Of Top Silo |

6 |

6 |

8 |

8 |

8 |

10 |

12 |

12 |

|

|

Qty. Of Hydraulic Pusher |

6 |

6 |

8 |

8 |

8 |

10 |

12 |

12 |

|

|

Preheating Capacity (t) |

600 |

600 |

800 |

800 |

800 |

1000 |

1600 |

1600 |

|

|

Rotary Kiln |

Size |

Φ2.8×42m |

Φ3.0×50m |

Φ3.2×50m |

Φ3.3×55m |

Φ3.6×55m |

Φ3.8×58m |

Φ4×60m |

Φ4.3×56m |

|

Slope |

3.50% |

3.50% |

3.50% |

3.50% |

3.50% |

3.50% |

3.50% |

3.50% |

|

|

Rotating Speed (r/min) |

0.3-1.8 |

0.3-1.8 |

0.3-1.8 |

0.3-1.8 |

0.3-1.8 |

0.3-1.8 |

0.3-1.8 |

0.3-1.8 |

|

|

Calcination Temperature (℃) |

1350 |

1350 |

1350 |

1350 |

1350 |

1350 |

1350 |

1350 |

|

|

Cooler |

Type |

Vertical |

Vertical |

Vertical |

Vertical |

Vertical |

Vertical |

Vertical |

Vertical |

|

Qty Of Temperature Control Area |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

|

|

Qty. Of Wind Tower |

4+1 |

4+1 |

4+1 |

4+1 |

4+1 |

4+1 |

4+1 |

4+1 |

|

|

Size(m) |

3.6×3.6 |

3.6×3.6 |

3.6×3.6 |

3.6×3.6 |

4.1×4.1 |

4.1×4.1 |

4.1×4.1 |

4.7×4.7 |

|

|

Output Temperature (℃) |

≤120 |

≤120 |

≤120 |

≤120 |

≤120 |

≤120 |

≤120 |

≤120 |

|

|

Product Thermal Loss(kcal/kg) |

5500 |

5400 |

5400 |

5400 |

5400 |

5400 |

5400 |

5000 |

|

|

Available Fuel |

Coke oven gas, mixed gas, natural gas, coal powder, low heating value coal gas |

||||||||

Related Project Case

200tpd Quick Lime Plant in Iran

Shanxi Jiangqiang Activity Lime Co., Ltd...

150 tons/day Lime Project in Uzbekistan

100TPD Shaft kiln For Quicklime Plant in...

50TPD Quick Lime Plant Project in Iran

Africa Congo 50,000 t/a Active Lime...

The whole-set equipment of Anyang lime...

Fugu Yihe Magnesium Co., Ltd lime...

Ningxia Baota Union Active Lime...