How to Choose the Buried Scraper Conveyor?

Date:2020-12-07 Source:zk corp Views:

When choosing buried scraper conveyor to transport materials, the following requirements are imposed on the materials:

(1) Material looseness: ρ=0.2-2.5t/m³.

(2) Material temperature: The applicable material temperature of the general model is less than 120℃; the temperature of the hot material conveying material is 100-450℃, and the instantaneous material temperature is allowed to reach 800℃.

(3) Moisture content: The moisture content is related to the particle size and viscosity of the material. Generally, it should be kneaded into a ball by hand and it can still be loose.

(4) Material particle size: suitable particle size<B/20, maximum particle size (≤10%)<B/10, (B is the effective width of the machine slot).

For materials with the following properties, buried scraper conveyors are generally not suitable:

(1) Materials with large suspension;

(2) Materials that are too large;

(3) Materials with high abrasiveness;

(4) Materials with excessive compressibility;

(5) Materials with high viscosity;

(6) Materials with strong liquidity;

(7) Materials that are fragile and do not want to be broken during transportation;

(8) Materials with hard characteristics;

(9) Corrosive materials should not be selected if there is no effective anti-corrosion measures.

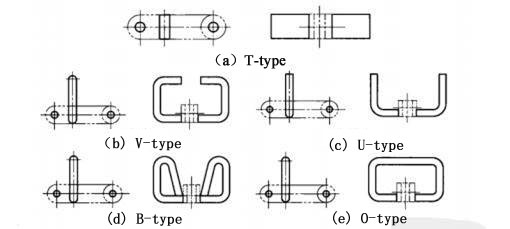

Figure 1 Scraper Type of Buried Scraper Conveyor

The scraper types of general purpose buried scraper conveyors are T-type, U-type, V-type, O-type and B-type; in actual selection, different types of scraper should be selected for conveying different materials.