Related Knowledge of Buried Scraper Conveyor

Date:2020-12-01 Source:zk corp Views:

Buried scraper conveyor is a continuous conveying equipment for conveying dust, small particles and small blocks and other bulk materials, which can be conveyed horizontally, inclinedly and vertically. When conveying, the scraper chain is all buried in the material, so it is called buried scraper conveyor.

Bulk materials have characteristics such as internal friction and side pressure.

Working principle of the horizontally conveyed buried scraper conveyor is:

When the traction member and scraper pass through the material loaded into the smooth surface of the chute, the material is pushed by the scraper chain in the direction of movement, and when the inner layer When the friction force is greater than the external friction force between the material and the material wall, the material moves forward with the scraper chain. The bulk material forms a continuous overall stream and is conveyed as the scraper moves forward. When the ratio of the height of the material layer to the width of the machine slot meets certain conditions, the material flow is stable.

Working principle of the vertical conveying buried scraper conveyor is:

The realization of vertical conveying mainly depends on the arching characteristics of the material. The material in the enclosed machine slot is pushed by the scraper chain in the direction of movement, and is also subjected to the resistance of the lower continuous feeding to prevent the upper material from sinking, thereby generating lateral pressure and increasing the internal friction of the material. When the internal friction is greater than the external friction between the material and the tank wall and the weight of the material, the bulk material will form a continuous overall material flow and be conveyed as the scraper chain moves upward. Because the scraper chain vibrates during movement, the material flow formed by some materials will be destroyed with the vibration of the chain. Therefore, a material flow lag will occur in the process of conveying materials, which will affect the overall performance of the buried scraper conveyor. Conveying capacity.

The buried scraper conveyor can be arranged horizontally, vertically, inclined or a combination of the three according to the process layout and plant conditions.

The specifications of the buried scraper conveyor are expressed by the width of the machine groove, for example: the width of the machine groove = 400mm, the specifications are expressed as MS40 or MS400. The groove width of the thermal buried scraper=400mm, and its specification is expressed as MSR40 or MSR400. Slot width of vertical buried scraper=400mm, its specification is expressed as MC40 or MC400.

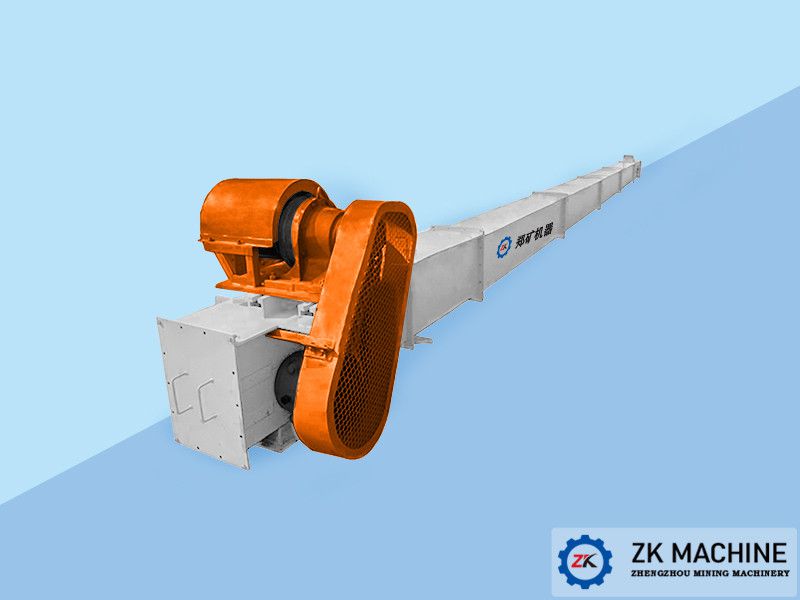

Composition and Application of Buried Scraper Conveyor:

The buried scraper conveyor is mainly composed of a closed section shell (machine groove), a scraper chain, a drive device and a tensioning device. The equipment has simple structure, small size, good sealing performance, convenient installation and maintenance; it can feed and discharge at multiple points, and the process selection and layout are more flexible; it is used for conveying flying, toxic, high-temperature, easily explosive materials It can improve working conditions and reduce environmental pollution. Buried scraper conveyors have been widely used in chemical, building materials, metallurgy, electric power, food, light industry and transportation sectors.