Reasons for the Deviation of the Linear Vibrating Screen Material

Date:2020-11-16 Source:zk corp Views:

It is a very common problem that the material deviation of the linear vibrating screen is in usage, mainly in the following aspects:

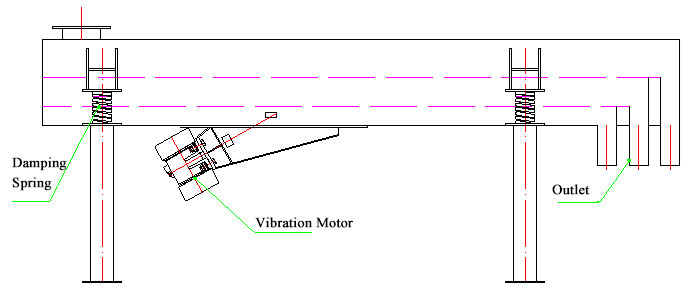

1. The installation position of the vibration motor is inappropriate.

Since the linear vibrating screen relies on the vibrating motor to screen the material, when the vibrating motor is installed at an inappropriate angle, it will cause the screened material to deviate.

2. The equipment has a heavy workload and running time is too long.

The long-term repeated vibration of the linear vibrating screen and the inertial body parts will loosen, which will cause the angle of the vibrating motor to change, and the material will deviate.

3. Uneven feeding

Uniform feeding is an indispensable requirement for linear vibrating screens. During operation, if the material is too frequent and less frequent, it is easy to cause unstable screening accuracy. The amount of material causes a large deviation in the force of the material, and the material is discharged to one side.

4. The damping spring of the vibrating screen is aging and loose.

The vibration screen's damping spring is loose, whether the position is changed, or aging will cause the screen surface to be unstable, causing the discharge to be biased to one side, and abnormal noise will occur in severe cases. The parts should be maintained and overhauled in time to prevent the parts from aging and damage. The damping spring should be selected with high quality and consistent stiffness.

5. The center of gravity of the vibrating screen body is unstable, and the position of the eccentric block of the motor is unbalanced.

6. Deformation of the vibrating screen box

The vibrating screen box is to withstand a large amount of materials and the exciting force of the vibrating motor. If the strength is not enough, it is easy to deform and damage the box.

7. The excitation force on both sides of the vibrating screen is unbalanced, resulting in inconsistent amplitudes on both sides and material deviation.

When a material deviation problem is found, it should be checked one by one in time, and the corresponding solution should be found to reduce the failure rate and increase the equipment utilization rate.