Comparison of belt conveyor tensioners device

Date:2016-10-26 Source:zk corp Views:

Tension device is divided into spiral, car and vertical, it is mainly for the normal operation of the belt to provide a certain tension, and ensure that the minimum tension point tension conveyor belt to compensate for the permanent extension of the conveyor belt. Choosing suitable tensioning device is the key to design the belt conveyor. Advantages and disadvantages of three kinds of tensioning device and the usage of comparison are as follows:

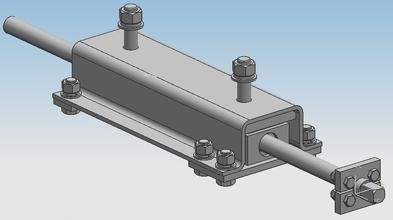

1. Screw tension device

Screw tension device installed in the belt of the tail wheel, by adjusting the screw so that the tail wheel displacement and thus into the conveyor belt, generally less than 60 meters in length smaller power belt machine, screw tension device travel can be belt Machine length of 1% of the selection. In the series of products in its trip is divided into 500mm, 800mm two. The role of the wheel on the conveyor belt point and two points of tension is tension for the garbage device.

Spiral tightening device is simple, small footprint, the drawback is not automatically adjust the tension of the conveyor belt, tension size should not be controlled, it is not appropriate to set the conveyor belt, such as automatic scales. In the important belt machine as far as possible not to use the screw tension device.

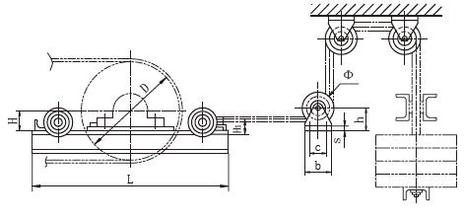

2. Car-type tension device

Car-type tensioning device is the belt conveyor tail wheel installed in the moving car, by the reversing pulley with a rope connected to mobile cars and heavy hammer, by the weight of the gravity hammer automatically tighten the conveyor belt, which effective tighten trip is:

S = (0.01-0.017) L

Formula : S ---- tension device effective travel (m);

L ---- belt machine real length (m)

Practice has proved that the tightening of the effective trip to take a larger appropriate.

The use of a wide range of car-type garbage device, not limited by the length of the belt conveyor tension can be automatically adjusted, simple and reliable structure, therefore the design priority.

3. The vertical tension device

Vertical tensioning device installed between the head wheel and the tail wheel should be as close as possible to the minimum tension at the conveyor belt (head wheel), when the belt machine starts, the vertical tension device action sensitive and effective. Its structure is the bottom side of the conveyor belt through the 90 ° to the drum, and then by the frame on the 180 ° to change the drum, hanging on the frame through the heavy hammer and the conveyor belt tension. The selection of the effective stroke is the same as that of the vehicle tensioning device.

Vertical tensioning device is Suitable for difficult occasions of car tensioning device. Its advantage is the usage of the belt conveyors length of the spatial location of the device to facilitate the layout. Disadvantages are the number of drums used to change, the material is easy to fall between the belt conveyor and roller to speed up the conveyor belt and roller wear. Especially when conveying moisture or viscous material, because cleaning is not in time, more serious wear and tear.