In Rotary Dryer, We Are More Professional

Date:2016-07-21 Source:zk corp Views:

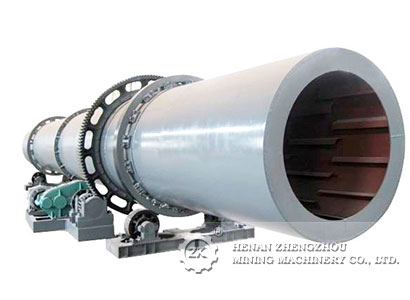

The drying is one of the basic thermal processes in industry. The drying process has a direct impact on the quality of the product, so we must pay enough attention to the drying equipment. Rotary dryer is a kind of industrial equipment, because of its wide application range, convenient operation, high operation rate, it is widely used in drying dressing, building materials, metallurgy, chemical, etc, As a professional rotary dryer supplier, Zhengzhou Mining Machinery Co., Ltd. introduce some technology problems about rotary dryer.

Rotary dryer is mainly composed of Supporting device before and after the roller device, import and export of material device, transmission device and the gear cover, etc. The main work process is as follows: The raw material gets into the cylinder from the feed box under the effect of the conveyor. The material flows back to the back end under the action of gravity and rotation, and forms a uniform curtain with the action of a copy. Hot gases generated by the lower hot blast stove move from below to the top, and contact with material. Hot air transmits heat to the material through heat conduction, convection, radiation and many other kinds of ways, so as to make the material temperature rise, water be evaporated. Water meet the material requirements is discharged from the lower exit and gas with water vapor from the chimney is fan out eventually.

Base aperture wears too fast is one of the important problems of rotary dryer appears. To understand the reasons for this phenomenon can remind us of doing some preventive measures against some problems, and then reduce the occurrence of base aperture wear. Both improper maintenance in In the course use and workers make the tube's total in dynamic state up to up and down can lead to grinding wheel into saddle shape or steps, it is difficult to cross the steps once the saddle shape or stepped shape formed. Improper base aperture adjustment also can make the cylinder can't normal running up and down so that roller and belting leather contact in the small scope, which result in a saddle or steps. It is also the cause of forming saddle or steps that measures did not be taken timely to adjust the position or relocation when belting leather and plate block wear to a certain value。

The phenomenon of red kiln is also a problem which is easy to occur during the operation of the dryer, which will seriously affect the normal operation of the rotary dryer. Therefore, solve the red on phenomenon is an important goal of the dryer manufacturers to pursue without downtime. If the cooling zone appears the phenomenon of the red kiln, silicon rate can be considered to reduce and the operation should be focused on improving the second air temperature into the kiln. This approach can only be operated by experienced operators, the strangers are not allowed to operate in order to avoid accidents or hazards.

Rotary dryer modified can significantly improve yield and reduce energy consumption. But the effect is not ideal after being transformed by some manufacturers. and even lead to that cylinder liner wear quickly, cylinder head and dryers is easy to burn out, shorten the service life of bag filter, etc, which causes the high cost of maintenance and affects the normal production. The problems above-mentioned sometimes are not caused by technical transformation, the main reason for the modification effect is that some rotary dryer suppliers mainly focus on the partial transformation of rotary dryer without considering the comprehensive balance problems about whole drying system.

Henan Zhengzhou Mining Machinary Co., Ltd, one of the rotary dryer suppliers, is an integrated modern enterprise collection of scientific research, design, development, manufacturing, sales, installation, commissioning and training services, provides you more comprehensive services. Choose us, Choose profession.

- Next Page: The Working Principle of Lime Vertical Kiln

- Previous: Several Common Cement Dryer Filters