We have rich project cases on different production process of ore dressing plant, Gold Ore Flotation Process, Gold Mine CIP Process Technology, Gold Ore Heap Leaching Process, Iron Ore Beneficiation Process, Fluorite Mineral Processing Technology, Lead-zinc Ore Dressing Process. More information about the mineral processing plant, please click there.

Raw material ores is exploited from mountain are big size,so it is necessary to crush firstly,in this process,the raw materials will be feed into primary crusher by feeder,then come into secondary crusher.The materials will go into screen after first and secondary crusher, the suitable size material (≤25mm) will go to next step. Oversize(>25mm) material will go back to secondary crusher to crush again. This forms a closed crush circuit.

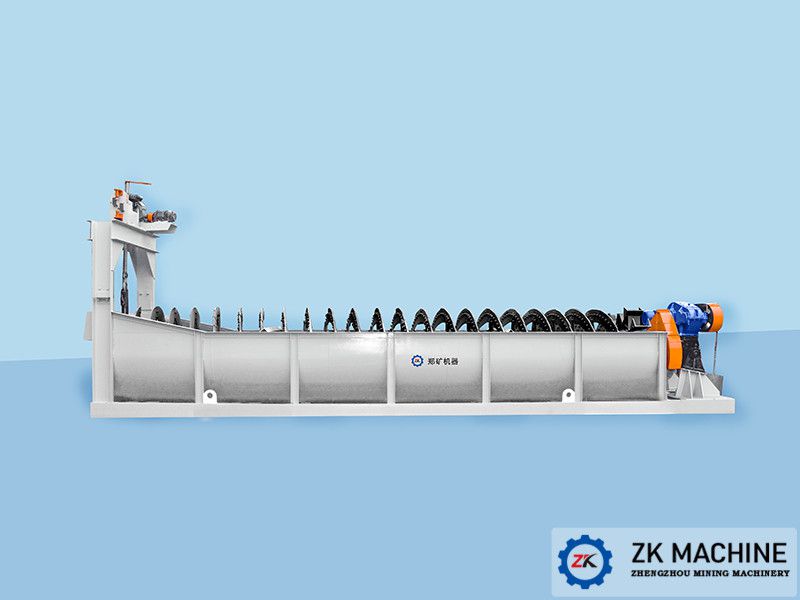

In this process, material will be grinded into suitable sizes (about 200 mesh) for beneficiation.After grinding material will come to classifier. In classifier, suitable size material will go to next step. Coarse material will go back to ball mill for grind again. This process is a closed grind circuit.

In this process, materials will be separated by flotation, magnetic separator or gravity concentrating machine. We will get the materials that we need.

Process introduction: After beneficiation, there are some residual water in ore concentration. So we have to carry on concentrate dehydration to meet the requirements of transportation and smelting.

LECA PRODUCTION LINE

LECA PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

CEMENT GRINDING STATION

CEMENT GRINDING STATION

CEMENT PRODUCTION LINE

CEMENT PRODUCTION LINE

LIME SLAKING PLANT

LIME SLAKING PLANT

MAGNESIUM OXIDE (MgO) PLANT

MAGNESIUM OXIDE (MgO) PLANT

LITHIUM PRODUCTION LINE

LITHIUM PRODUCTION LINE

ORE DRESSING LINE

ORE DRESSING LINE

GYPSUM POWDER PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

ALUMINUM ASH PROCESSING SYSTEM

ALUMINUM ASH PROCESSING SYSTEM

FRACTURING PROPPANT PRODUCTION LINE

FRACTURING PROPPANT PRODUCTION LINE

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

PULVERIZED COAL PREPARATION PRODUCTION LINE

PULVERIZED COAL PREPARATION PRODUCTION LINE

GGBS PRODUCTION LINE

GGBS PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

FLUE GAS PURIFICATION SYSTEM

FLUE GAS PURIFICATION SYSTEM

FGD SYSTEM

FGD SYSTEM

SOIL REMEDIATION SYSTEM

SOIL REMEDIATION SYSTEM

SUSPENSION ROSTING FURNACE TEST LINE

SUSPENSION ROSTING FURNACE TEST LINE

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

LITHIUM BATTERY RECYCLING LINE

LITHIUM BATTERY RECYCLING LINE

ALUMINA CALCINING LINE

ALUMINA CALCINING LINE

WASTE-COPROCESSED BUILDING MATERIAL MANUFACTURING

WASTE-COPROCESSED BUILDING MATERIAL MANUFACTURING