Introduction

TH Series Chain Bucket Elevator is a kind of continuous vertical lifting equipment with chain type bucket to process bulk material. It is mainly used for lifting bulk material and crushed material with the property of low hardness. It is widely used in power, chemistry, metallurgy, building material, mining and etc. The lifted material with the temperature under 250℃. It has the features of high capacity, reliable working, small area needed, high lifting height and easy maintenance. In the driving system, it has the high reliable non-return structure to prevent temporary power off or other fault causing shut off under the loading condition to make drive and lifting hopper return moving to cause fault.

Application of Chain Bucket Elevator:

Chain Bucket Elevator is used for lifting powder, granular materials and small block and grinding of small materials vertically, such as: coal, cement, stones, sand, clay, ore and so on. or other industries of dry mortar for construction, chemistry and foodstuff.

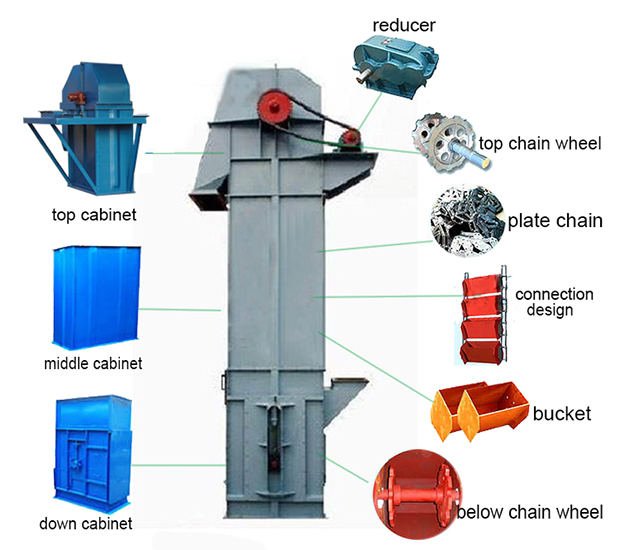

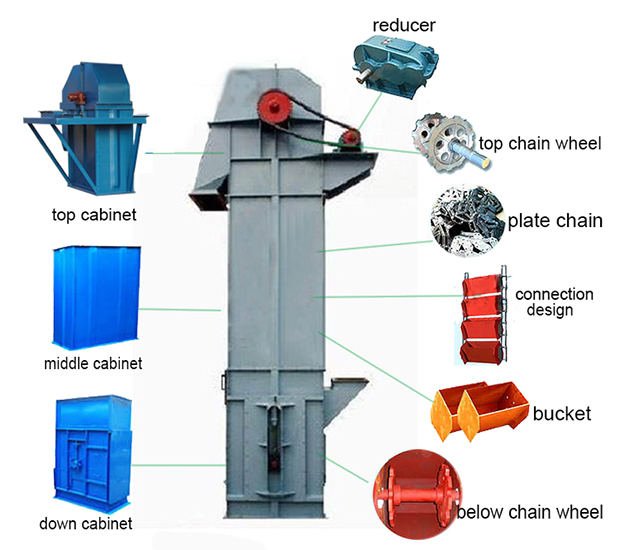

Structure of Chain Bucket Elevator

Features

1. Compact Machine Structure, small overall dimension, small space needed.

2. Adopt the taking out type material loading and mixing type material discharging. The hopper volume is big with high density layout. It has the feature of big lifting scope, high lifting height and high transportation capacity.

3. Each section and maintenance door have the sealing device to make sure no dust outlet to realize clean and friendly environment production.

4. Drive sprocket wheel is a overall structure, the surface has been specially strengthen processed. It has the features of easy operation, high strength and wearing resistance.

5. Adopt low alloy high strength round ring chain as driving part. Under the special technology process, it has the features of anti-pulling strength, good wearing resistance, long time using, good hopper connection, and easy to be maintenance.

Technical Parameter

| Model | Type | Capacity (m³/h) | Hopper | Drive Revolving Speed | Max Size | Elevating Height |

|---|

| Volume | Bucket Pitch | Bucket Width | Speed |

|---|

| Deep Bucket | Shallow Bucket | Deep Bucket | Shallow Bucket | (mm) | (mm) | (m/s) | (r/min) | (mm) | (m) |

|---|

| TH160 | Centrifugal Chain Type | 25.00 | 15.00 | 1.90 | 1.20 | 500 | 160 | 1.20 | 69.71 | 20 | 3.88~38.38 |

| TH250 | Centrifugal Chain Type | 48.00 | 31.00 | 4.60 | 3.00 | 500 | 250 | 1.20 | 44.11 | 30 | 4.11~38.11 |

| TH315 | Centrifugal Chain Type | 60.00 | 35.00 | 6.00 | 3.75 | 512 | 315 | 1.40 | 42.50 | 35 | 4.55~38.05 |

| TH400 | Centrifugal Chain Type | 94.00 | 60.00 | 9.50 | 5.90 | 512 | 400 | 1.40 | 37.60 | 40 | 4.50-38.00 |

Note: The volume of the hopper in the table is the volume when the hopper is filled with water, which is similar to the actual filling volume. Therefore, the filling factor is not considered in the calculation formula of the conveying volume. The filling factor should be determined according to the particle size of the material in the specific selection, so as to correct the conveying volume given in this table.

Project Cases

LECA PRODUCTION LINE

LECA PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

CEMENT GRINDING STATION

CEMENT GRINDING STATION

CEMENT PRODUCTION LINE

CEMENT PRODUCTION LINE

LIME SLAKING PLANT

LIME SLAKING PLANT

MAGNESIUM OXIDE (MgO) PLANT

MAGNESIUM OXIDE (MgO) PLANT

LITHIUM PRODUCTION LINE

LITHIUM PRODUCTION LINE

ORE DRESSING LINE

ORE DRESSING LINE

GYPSUM POWDER PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

ALUMINUM ASH PROCESSING SYSTEM

ALUMINUM ASH PROCESSING SYSTEM

FRACTURING PROPPANT PRODUCTION LINE

FRACTURING PROPPANT PRODUCTION LINE

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

PULVERIZED COAL PREPARATION PRODUCTION LINE

PULVERIZED COAL PREPARATION PRODUCTION LINE

GGBS PRODUCTION LINE

GGBS PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

FLUE GAS PURIFICATION SYSTEM

FLUE GAS PURIFICATION SYSTEM

FGD SYSTEM

FGD SYSTEM

SOIL REMEDIATION SYSTEM

SOIL REMEDIATION SYSTEM

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

LITHIUM BATTERY RECYCLING LINE

LITHIUM BATTERY RECYCLING LINE

ALUMINA CALCINING LINE

ALUMINA CALCINING LINE