Introduction

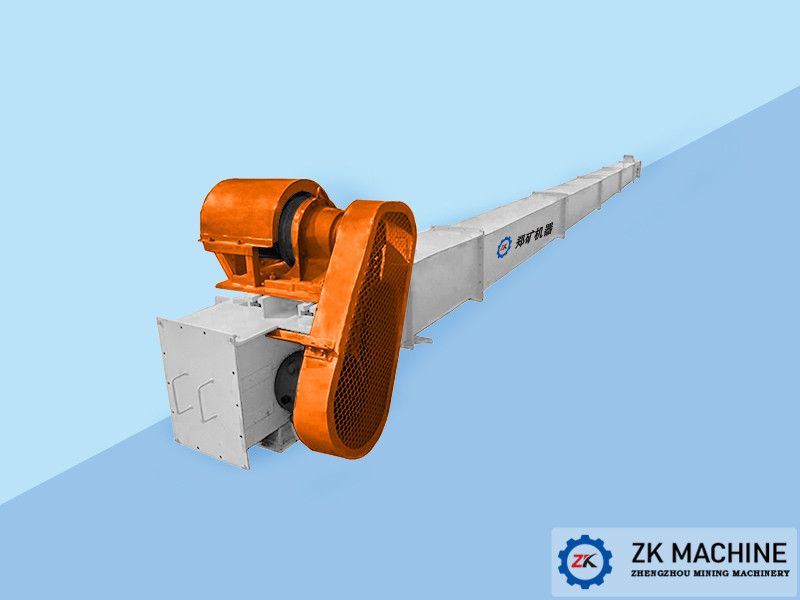

Screw conveyor has features of compact structure, small cross-sectional area, ligh weight, good sealing, high efficiency, flexible arrangement. It is convenient to assemble, dismantle, move and safety operation. It is suitable to convey all kinds of powdery, granular bulk materials, such as clay powder, coal, cement, sand, small lump coal, gravel, scrap iron etc. But not suitable for sticky agglomerate, perishable materials. Screw conveyor has horizontal and inclined arrangement. It can work with other conveying device to complete the concentrated transportation, distribution, agitation, mixing, dehydration, dosing, unload, stacking operation etc.

Application of Screw Conveyor

Screw conveyor generally used for continuity conveying bulk materials in short distance at horizontal or slightly oblique (angle β≤15 °) direction. It can mix and stir the material during conveying. The working environment is -20 ~ 50 ℃, and the material should be less than 200 ℃. Its design and fabrication meet the professional standards in JB/T7679-2008-"screw conveyor". The hanging bearing adopts the two structures of rolling and sliding interchangeable. It has low resistance, strong sealing and good wear resistance.

Types of Screw Conveyor

Scerw Conveyor in the form of transmission is divided into shaft screw conveyor and shafless screw conveyor, in the shape is divided into U-type screw conveyor and tube screw conveyor.

Scerw Conveyor in the form of transmission is divided into shaft screw conveyor and shafless screw conveyor, in the shape is divided into U-type screw conveyor and tube screw conveyor.

Scerw Conveyor in the form of transmission is divided into shaft screw conveyor and shafless screw conveyor, in the shape is divided into U-type screw conveyor and tube screw conveyor.

Features

1. It achieved clean and environmentally friendly production, especially suitable for conveying dusty, hot (under 200 ℃) and sharp odour material.

2. The wear treated screw is more wearable and stronger than traditional common screw. It can significantly increase the service life of the screw

3. It can achieve multi-point feeding and multi-point discharging according to user's process layout.

4. The redesigned discharging structure makes the discharging smoother.

5. Compact structure, less wearing parts, convenient to install, operate and maintain.

Technical Parameter

| Main technical parameters of GX series screw conveyor |

|---|

| Revolving speed (r/min) | Model |

|

|---|

| GX150 | GX200 | GX250 | GX300 | GX400 | GX500 | GX600 |

|

|---|

| Capacity (m³/ h) |

|

|---|

| 20 | 0.9 | 2.1 | 4.1 | 7.1 | 16.8 | 32.9 | 56.9 |

|

| 30 | 1.3 | 3.2 | 6 2 | 10.7 | 25 3 | 49.4 | 85.3 |

|

| 35 | 1.5 | 3.7 | 7.2 | 12.4 | 29.5 | 57.6 | 99.5 |

|

| 45 | 2 | 4.7 | 9.3 | 16 | 37.9 | 74 | 127.9 |

|

| 60 | 2.6 | 6.3 | 12.3 | 21.3 | 50.5 | 98.7 | 170.6 |

|

| 75 | 3.3 | 7.6 | 15.4 | 26.6 | 63.2 | 123.3 | 213.2 |

|

| 90 | 4 | 9.5 | 18.5 | 32 | 75.8 | 148 | 255.9 |

|

| Main technical parameters of LS series screw conveyor |

|---|

| Model | Spiral diameter (mm) | Pitch (mm) | Max rev. speed (r/min) | Max. capacity (m³/ h) |

|---|

| Fill coefficient |

|---|

| Φ=0.45 | Φ=0.33 | Φ= 0.15 |

|---|

| LS100 | 100 | 100 | 140 | 3 | 2.2 | 1 |

| LS125 | 125 | 125 | 125 | 5.2 | 3.8 | 1.7 |

| LS160 | 160 | 160 | 112 | 9.7 | 7.1 | 3.2 |

| LS200 | 200 | 200 | 100 | 16.9 | 12.4 | 5.6 |

| LS250 | 250 | 260 | 90 | 29.7 | 21.8 | 9.9 |

| LS315 | 315 | 315 | 80 | 52.9 | 38.8 | 17.6 |

| LS400 | 400 | 355 | 71 | 85.3 | 62.5 | 28.2 |

| LS500 | 500 | 400 | 63 | 133.2 | 97.7 | 44.4 |

| LS630 | 630 | 450 | 50 | 188.9 | 138.5 | 63 |

| LS800 | 800 | 500 | 40 | 270.7 | 198.5 | 70.2 |

| LS1000 | 1000 | 560 | 32 | 379 | 277.9 | 126.3 |

| LS1250 | 1250 | 630 | 25 | 520.5 | 381.7 | 173.5 |

Project Cases

LECA PRODUCTION LINE

LECA PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

CEMENT GRINDING STATION

CEMENT GRINDING STATION

CEMENT PRODUCTION LINE

CEMENT PRODUCTION LINE

LIME SLAKING PLANT

LIME SLAKING PLANT

MAGNESIUM OXIDE (MgO) PLANT

MAGNESIUM OXIDE (MgO) PLANT

LITHIUM PRODUCTION LINE

LITHIUM PRODUCTION LINE

ORE DRESSING LINE

ORE DRESSING LINE

GYPSUM POWDER PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

ALUMINUM ASH PROCESSING SYSTEM

ALUMINUM ASH PROCESSING SYSTEM

FRACTURING PROPPANT PRODUCTION LINE

FRACTURING PROPPANT PRODUCTION LINE

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

PULVERIZED COAL PREPARATION PRODUCTION LINE

PULVERIZED COAL PREPARATION PRODUCTION LINE

GGBS PRODUCTION LINE

GGBS PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

FLUE GAS PURIFICATION SYSTEM

FLUE GAS PURIFICATION SYSTEM

FGD SYSTEM

FGD SYSTEM

SOIL REMEDIATION SYSTEM

SOIL REMEDIATION SYSTEM

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

LITHIUM BATTERY RECYCLING LINE

LITHIUM BATTERY RECYCLING LINE

ALUMINA CALCINING LINE

ALUMINA CALCINING LINE