Introduction

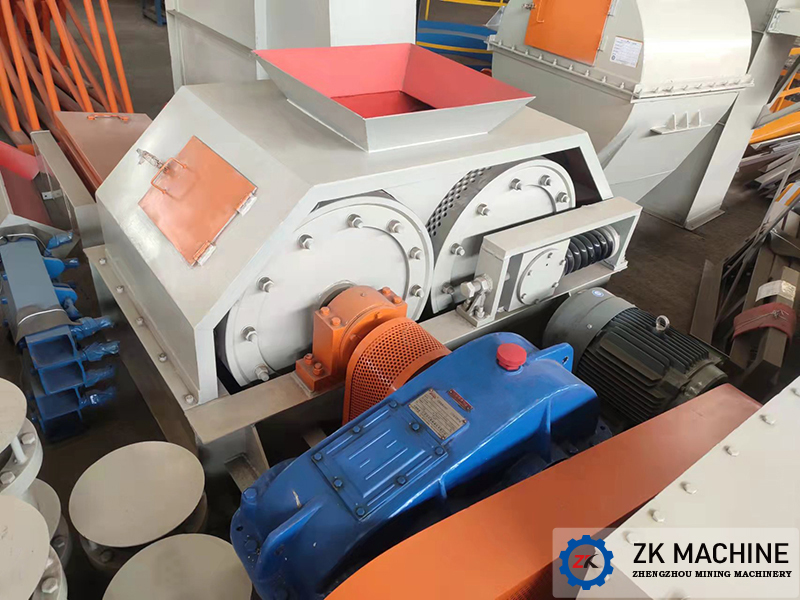

The double roll granulator is a molding equipment capable of forming a powder or small granular material into a specific shape, and is mainly composed of a movable roll device, a fixed roller device, a roller support bearing, an adjusting device, and a driving device. It is characterized by smoothness, low noise, less dust, reliable performance and convenient maintenance. It can be widely used in construction, mining and metallurgy, environmental protection and other industries.

Working Principle

The working principle is that the geared motor drives the fixed roller to rotate through the chain drive. When the fixed roller rotates, the movable roller that is in contact with it is rotated by the friction of the roller surface, and the material slides from the feeding chute into the roller granulator and is pressed by the roller. The material is extruded through a fixed roll hole, and the formed material is cut off by the scraper and discharged from the outlet.

The granulator has the characteristics of uniform granulation, high yield, large output, compact structure, reasonable layout, small floor space and high automation.

Features

1. With advanced technology and stable quality, this type of roller granulator developed for the calcination characteristics of ceramsite has won unanimous praise from customers.

2. High production efficiency, high ball formation rate.

3. The discharging is uniform. The ceramsite produced by the roller granulators is uniform in size, which can meet the requirements of the ceramsite rotary kiln for the size and shape of the ball.

4. The overall operation of the equipment is stable and the noise is low. At the same time, it adopts the sealed cover to receive the material, and the site is clean and tidy, reducing the labor intensity of the workers.

Technical Parameter

| Model | Roller diameter(mm) | Roller length(mm) | Extrusion bore diameter(mm) | Roller rotating speed(r/min) | Capacity(t/h) | Installed power(kW) |

|---|

| GL450×400 | 450 | 400 | 8-16 | 58 | 2-5 | 11 |

| GL610×700 | 610 | 700 | 8-16 | 40 | 5-8 | 18.5 |

| GL700×600 | 700 | 600 | 8-16 | 36 | 5-8 | 18.5 |

| GL800×700 | 800 | 700 | 8-16 | 30 | 8-12 | 18.5 |

| GL1000×900 | 1000 | 900 | 8-16 | 26.4 | 10-15 | 30 |

Project Cases

LECA PRODUCTION LINE

LECA PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

CEMENT GRINDING STATION

CEMENT GRINDING STATION

CEMENT PRODUCTION LINE

CEMENT PRODUCTION LINE

LIME SLAKING PLANT

LIME SLAKING PLANT

MAGNESIUM OXIDE (MgO) PLANT

MAGNESIUM OXIDE (MgO) PLANT

LITHIUM PRODUCTION LINE

LITHIUM PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

ALUMINUM ASH PROCESSING SYSTEM

ALUMINUM ASH PROCESSING SYSTEM

FRACTURING PROPPANT PRODUCTION LINE

FRACTURING PROPPANT PRODUCTION LINE

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

PULVERIZED COAL PREPARATION PRODUCTION LINE

PULVERIZED COAL PREPARATION PRODUCTION LINE

GGBS PRODUCTION LINE

GGBS PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

FLUE GAS PURIFICATION SYSTEM

FLUE GAS PURIFICATION SYSTEM

FGD SYSTEM

FGD SYSTEM

SOIL REMEDIATION SYSTEM

SOIL REMEDIATION SYSTEM

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS