Guide for model selection of Drum Screen: Based on the comprehensive consideration of material characteristics and production needs!

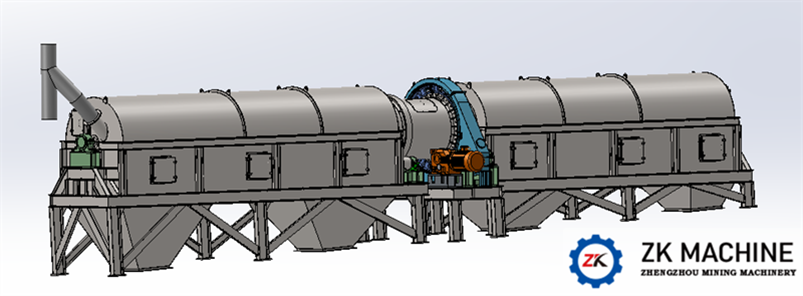

As a widely used screening equipment, drum screen plays an important role in mining, building materials, chemical industry, and other industries. The correct selection of the drum screen is crucial to ensure production efficiency and product quality.

The following is the main basis that should be considered when the drum screening type

1. Material characteristics

1.1 Particle size distribution: The particle size of the material directly affects the screening efficiency, and different particle sizes of the material need to match the corresponding screen size to achieve the best screening effect.

1.2 Humidity: High humidity materials can affect screening performance and even lead to screen clogging, so choose a roller screen suitable for wet materials.

1.3 Viscosity: Sticky materials are easy to caking, it is recommended to use a drum sieve with internal percussion device to prevent material adhesion.

2. Production Capacity

Determine the diameter and length of the drum screen according to the required processing volume. Generally, the larger the diameter and the longer the length of the drum screen, the stronger the processing capacity.

3. Screening Accuracy Select the appropriate screen size according to the granularity requirements of the final product. The size of the screen directly determines the size range of the final product.

4. Equipment size and site limitations

Before selecting the drum screen, it is necessary to consider the size of the installation space and the convenience of maintenance to ensure that the equipment can be smoothly installed and convenient for daily maintenance.

5. Energy consumption and environmental requirements

Choosing a roller screen with low energy consumption and environmental protection standards helps reduce production costs and responds to the call for green production.

6. Economy

Under the premise of meeting the requirements of use, comprehensively evaluate the purchase cost, operating cost and subsequent maintenance cost, and select the most cost-effective equipment.

7. Reliability and durability

The working environment of the drum screen is usually harsh, and its structural strength and durability are important considerations when selecting.

8. Leve of automation

With the development of automation technology, many drum screens are equipped with automatic control functions, which can automatically adjust the speed and other parameters according to the actual production situation to improve work efficiency.

To sum up, the selection of the appropriate drum screen needs to consider the material characteristics, production capacity, screening accuracy and other aspects. Correct selection can not only improve production efficiency, but also reduce operating costs and extend the service life of equipment.