Difference and selection between screening equipment in mining industry

Mining screening equipment is the process of improving mining materials by separating materials of different sizes and removing the dust of mining materials from unwanted undersized particles. It consists of a screen and a drive system that separates fine particles from For coarse particle separation, the drive system produces the necessary vibration or rotation to move, loosen and transport the screened material on the screen plate.

1. Types of mining screening equipment.

Mining screening equipment can be distinguished according to its working principle and application materials, mainly including vibrating screens and drum screens (vibrating screens are divided into circular vibrating screens and linear vibrating screens). Each screen type is designated for specific purposes and application, the following is a detailed introduction.

2.What is the difference between vibrating screen and trommel screen?

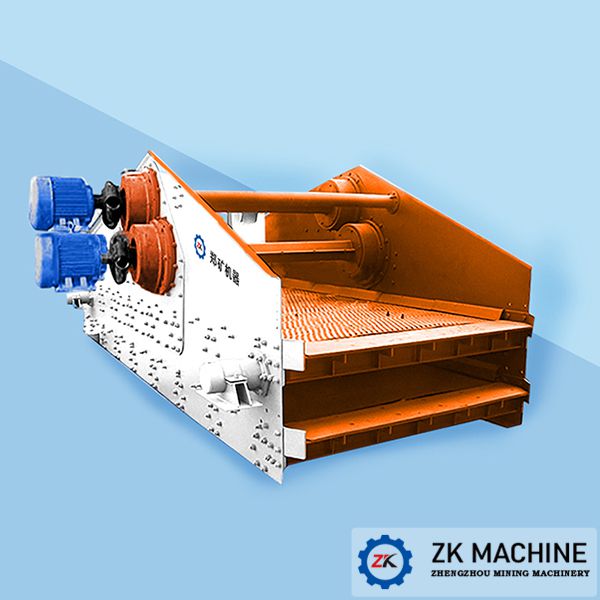

2.1 Its working principle is different: the vibrating screen uses a vibrating motor to drive the screen box to vibrate, and the materials make linear jumping movements on the screen surface. The materials are divided into materials of different particle sizes according to different mesh sizes.

During the screening process of the drum screen, the equipment will not vibrate, but generally the motor and reducer will rotate the drum through the bearing. The material in the drum will successfully screen out the sand due to the rotation of the drum and the size of the screen mesh.

2.2 Screening accuracy and output are different: The vibrating screen is a screening equipment with a vibration motor as the vibration source. Therefore, the screening accuracy is high, and the corresponding screening output is not too high.

The trommel screen is a high-capacity screening equipment with high screening output, but the corresponding screening accuracy is not as high as that of the vibrating sand screen.

3. What is the difference between circular vibrating screen and Linear screens

According to the different running trajectories of the screen, the vibrating screen can be divided into circular vibrating screen and linear vibrating screen.

3.1 Circular vibrating screens mainly screen materials with heavy specific gravity, large particles and high hardness. They are widely used in mining, coal, quarry plants and other mining industries. They are ideal equipment for processing materials after primary crushing and secondary crushing. They can also be used for screening. Divide finished materials into finished products.

3.2 Linear screens mainly screen materials with medium to fine particles, light specific gravity, and low hardness. They are usually widely used in the food, chemical, building materials, and pharmaceutical industries. The screen surface moves back and forth in a straight line, and the material layer above moves forward while , it is also compacted during the jumping and falling process, so it is especially suitable for dehydration, demediation, deliquification and heavy medium removal during heavy medium mineral processing, and is widely used in coal preparation plants.