The Fuel Selection for Ceramsite Calcined in Rotary Kiln

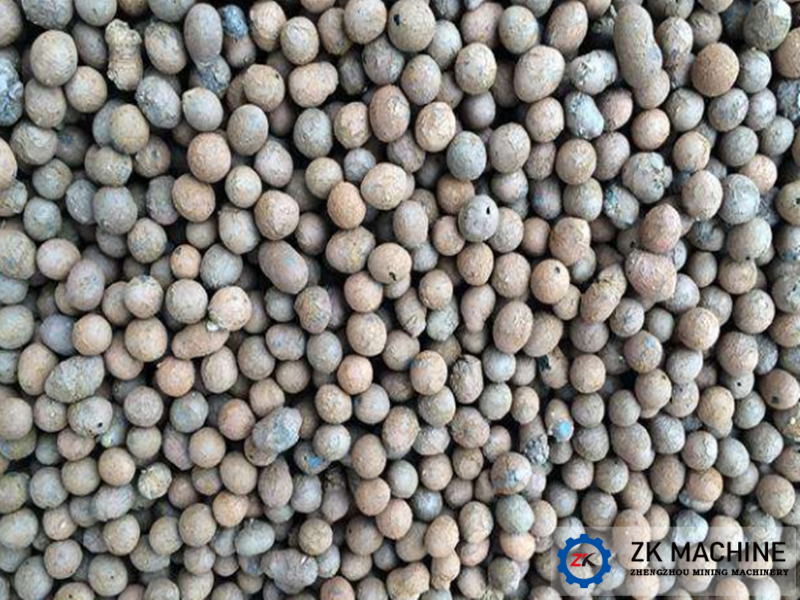

Ceramsite is a kind of light aggregate that is calcined in a rotary kiln at high temperature and foamed and expanded. The surface is smooth and the inside is porous. It has the characteristics of small density, high strength, thermal insulation, fire resistance and earthquake resistance, and is widely used in the construction industry, such as concrete blocks, light partition walls, floor filling, etc. Rotary kiln firing of ceramsite requires a high temperature of 1050-1250 ° C and is provided by fuel.

Generally speaking, fuel in industrial production is divided into gas fuel (natural gas, etc.), solid fuel (such as raw coal, coal powder, biomass particles etc.), liquid fuels (heavy oil, petroleum, alcohol, etc.), common natural gas, coal, petroleum, etc. these fuels can be used in rotary kilns, but not all are suitable for the ceramsite industry.

Natural gas is a gas fuel with a calorific value of 8500kcal / m³. It has the advantages of easy combustion, no ash and high efficiency. It is a clean, efficient and high-quality natural fuel. Compared with other fuels, the overall cost is higher.

As a solid fuel, coal has a calorific value of 7000kcal / kg and is cheap. For ceramsite enterprises, it has good economy and is the preferred fuel. However, coal also has several significant disadvantages: one is combustion will cause environmental pollution such as acid rain; second, the resource reserves are decreasing; third, it cannot be fully burned, and a small amount is wasted. The usage of coal is controlled by the state and the conditions are more demanding. Whether it is clean energy natural gas or fuel coal with good economy, they are non-renewable resources and have limited reserves.

The other solid fuel, bran, is crushed from rice husk. It is a biomass fuel. It is a renewable resource with a calorific value of 4200kcal / kg. And it has the advantages of low price and abundant stock.

At present, ceramsite is in great demand in the surrounding markets of Jiangsu. The ceramsite plants are mainly built in these places, but there are no coal mines in the local area. A small number of coal mines in the surrounding cities are mainly supplied to steel mills, and the surrounding cities are rich in grain sugar. The industry generally uses bran as fuel. In summary, the usage of bran as fuel for rotary kilns in ceramsite plants in Jiangsu and other places is due to the choice of local special geographical regions, and coal mines are more suitable for use in the northwest region. Henan Zhengzhou Mining Machinery CO.,Ltd. has been engaged in the ceramsite industry for many years and has rich technical accumulation and project experience. If you want to know more about ceramsite production equipment, welcome to visit our factory for inspection!