How is the process flow of energy-saving lime rotary kiln?

As a leading manufacturer of lime rotary kiln, we improved the technology of our lime rotary kiln and developed a series of rotary kilns with patents based on the concept of economically, environmentally, and high efficiency. Due to our perfect automation control technology, our lime rotary kilns are at high level domestically to realize high-efficiency automatic production and achieve target of environment protecting. This lime rotary kiln, which is equipped with vertical pre-heater and vertical cooler, has the properties of high utilization, well calcination, high fine, high yield, high working ratio, environmental protection, easy operation and high automation. It is especially suitable for the limestone calcination in metallurgy, steel and chemical industries.

I. As the Industrial Leader with the Perfect Technology

The lime rotary kiln is a new type of environmental protecting equipment. The main drive system adopts AC frequency conversion speed adjustment, which is more environment protection, larger speed adjustment scope, high efficiency and accuracy and more stable performance compared with the traditional electromagnetic and DC speed adjustment.

Vertical preheater adopted with advanced structure and low-pressure lost could save 40% fuel index and increase 30% capacity. The exhaust had been recycled and re-cleaned. The exhaust index can be 30mg/m³.

According to the limestone property and calcination requirements, we improve the structure of the kiln end part to solve the problem of material reverting and dust leakage, which makes the conveying more smoothly. The heat exchange method between top and end of rotary kiln can decrease the heat lost as much as possible.

II. High Quality, High Yield and Energy-Saving

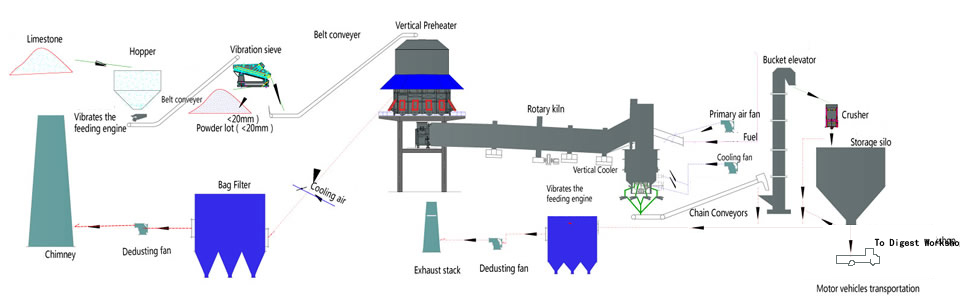

The energy-saving lime kiln can distribute preheating part, calcining part and cooling part into inner kiln scientifically, so as to take full advantage of the material heat. The material is brought from the top cabin of pre-heater to pre-heater through pipe. Meanwhile, the high temperature smoke enters to rotary kiln and preheats the material to 1000℃or above. When the lime have decomposition, the hydraulic rod would push materials to the end of rotary kiln where the materials have high-temperature calcination. Then the materials are cooled by cooling wind in the cooler. Once the temperature of materials is below 60℃, materials will be discharged. The air from cooler as secondary air is burnt in the rotary kiln. The whole progress is close and automatic. The exhaust gas reach the requirements of environment protection. It is realized to high quality, high capacity, energy saving as well as environment protection.

III.Equipped with Dust Removal Equipment for a Green Plant

High temperature smoke from rotary kiln burnt and limestone exchanges heat in the preheater. When the temperature is below 250℃, the smoke will go into the centrifugal dust separator and finish the first step dust collection. The further dust collecting is done by bag fliter. After the whole dust collecting, the cleaned exhaust gas is discharged by high temperature fan. The strength of exhaust gas is below 30mg/m³, which meets the requirements of modern environment protection. The dust collector is equipped with cooling exhaust system to protect the collector.

The lime calcined by our lime rotary kiln is in high activity. The technology design is very flexible, which can be equipped with the vertical preheat in the end of kiln to take full advantage of high temperature smoke from rotary kiln calcination, which heat the limestone from the normal temperature to initial decomposition. The kiln head could be equipped with vertical cooler to cool the high temperature limestone in a short time, to improve lime activity and also easy for storage and transportation. We have many successful cases in this field, such as a lime production line with capacity 250,000 tons per year for Fugu Jingfu, a lime production line with capacity 200,000 tons per year for Shanxi Jiangqiang. For more industry news and quotation, you are welcomed to contact us.