This project is mainly to transform the roll granulator on the original ceramsite production line, and to improve the granulation rate of the original granulator.

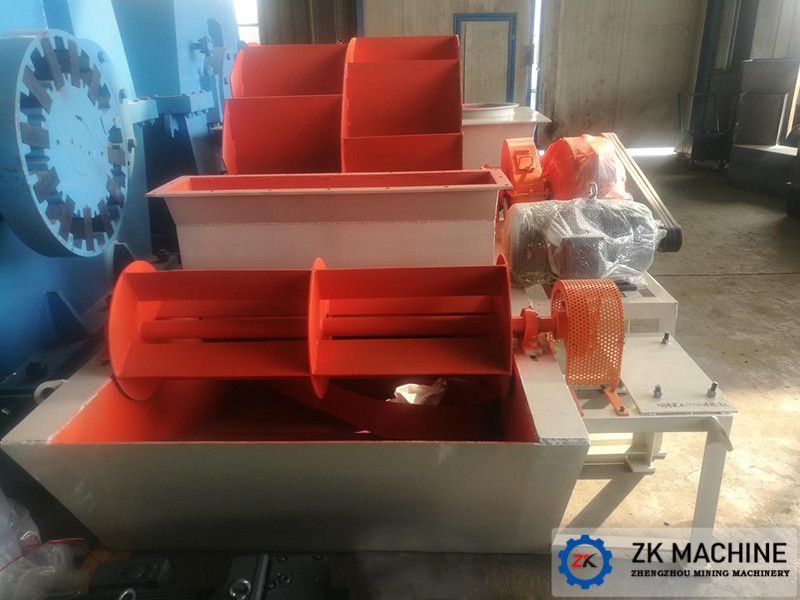

The equipment supplied this time is a roller granulator and a sand making machine, which have the following characteristics:

1) The counter-roll granulator is a newly designed equipment. It is driven by a chain to realize the synchronous rotation of the driven roller and the driven roller. Compared with the frictional rotation of the traditional driven roller by the driven roller, it can prevent slippage and increase the output.

2) The double-roll granulator has high production efficiency, and the ball forming rate reaches more than 90%.

3) The ceramsite produced by this pair of roller granulator is uniform in size and can be continuously produced, which can meet the requirements of the ceramsite rotary kiln for the size and shape of the pellets.

4) On the basis of the traditional working mode of the sand making machine, a rotary impeller device is added in front to ensure that the materials entering the sand making machine are dispersed and the feeding is uniform, so as to improve the sand making output.

LECA PRODUCTION LINE

LECA PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

CEMENT GRINDING STATION

CEMENT GRINDING STATION

CEMENT PRODUCTION LINE

CEMENT PRODUCTION LINE

LIME SLAKING PLANT

LIME SLAKING PLANT

MAGNESIUM OXIDE (MgO) PLANT

MAGNESIUM OXIDE (MgO) PLANT

LITHIUM PRODUCTION LINE

LITHIUM PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

ALUMINUM ASH PROCESSING SYSTEM

ALUMINUM ASH PROCESSING SYSTEM

FRACTURING PROPPANT PRODUCTION LINE

FRACTURING PROPPANT PRODUCTION LINE

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

PULVERIZED COAL PREPARATION PRODUCTION LINE

PULVERIZED COAL PREPARATION PRODUCTION LINE

GGBS PRODUCTION LINE

GGBS PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

FLUE GAS PURIFICATION SYSTEM

FLUE GAS PURIFICATION SYSTEM

FGD SYSTEM

FGD SYSTEM

SOIL REMEDIATION SYSTEM

SOIL REMEDIATION SYSTEM

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS