Introduction

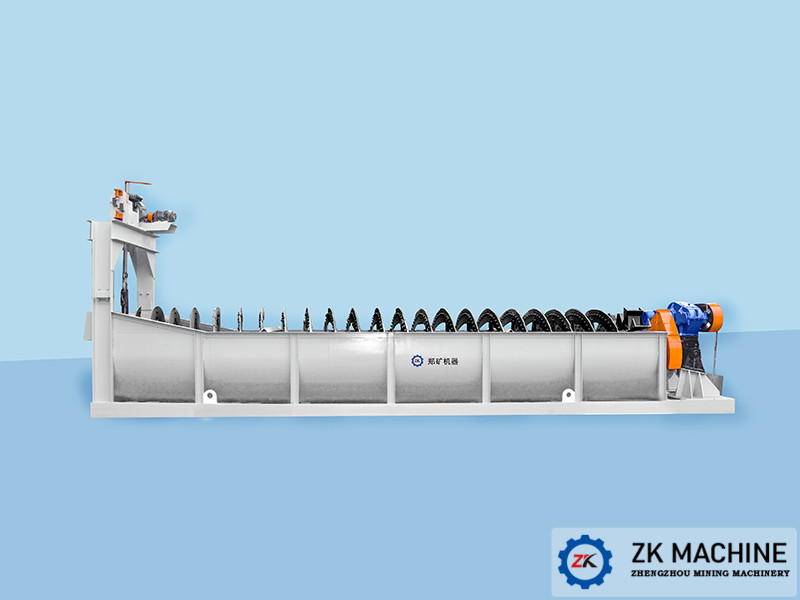

Double shaft mixer is a device that uses the synchronous rotation of a pair of spiral shafts with mixing blades to convey powdery materials while humidifying and stirring them. It has advantages of high mixing efficiency, compact structure, stable operation, cleanness and environmental protection. The acid mixing machine for lithium battery new energy is acid-resistant and corrosion-resistant.

Application:

Used in chemical, mining, power generation, ceramsite and other industries to humidify, stir and transport power plant fly ash, sludge, clay and other solid granular materials or powders. It can also be used to add acid to lithium battery new energy materials, mixed acid and other processes.

Working Principle:

The transmission device (gear box) drive two shafts to opposite direction synchronously. When the material fed, the water sprayer(optional device) starts to work to wet the material. The blades on shafts mix the material with water or other material, and push mixed material forward, and discharge the material to outlet.

Features

1. The entire mixing and conveying process is carried out in a confined space, no dust leakage, clean and environmentally friendly;

2. Integrate mixing, humidification and conveying, with good mixing uniformity, high production efficiency and large capacity;

3. The mixing blade is made of wear-resistant material and has been specially treated with a special surface to have high wear resistance;

4. The whole machine is compact in structure, small in space, stable in transmission, high in reliability and low in noise.

5. The whole machine has compact structure, small space occupation, stable transmission, high reliability and low noise.

6. The blades and shafts of the acid mixing machine are treated with ceramic patches or tungsten carbide spraying for acid and corrosion resistance.

Technical Parameter

SJ series twin-shaft mixer is suitable for mixing viscous materials such as sludge, oil sludge, coal slime, bentonite, etc. The materials are highly viscous and difficult to stir.

| Model | SJ□×30 | SJ□×32 | SJ□×35 | SJ□×40 | SJ□×42 | SJ□×46 | SJ□×50 | SJ□×60 |

| Center distance between two axes/mm | 300 | 320 | 350 | 400 | 420 | 460 | 500 | 600 |

| Rotating speed of main axes/(r/min) | 53 | 53 | 53 | 53 | 53 | 53 | 45 | 45 |

| Stirring tank length/mm | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-4000 |

| Capacity/m³ | >6-8 | >8-10 | >10-13 | >13-24 | >24-28 | >28-35 | >35-38 | >38-80 |

| Motor Power/kW | 22 | 30 | 37 | 45 | 55 | 75 | 75 | 110 |

Notes:1. The production capacity in the equipment table is when the blade inclination angle is 15 degrees and the filling system is 0.33.

2. The power in the equipment table is the power when the bulk density is 1.0-1.3.

3.This series of double-shaft mixers is equipped with ZQ series soft tooth surface reducer and ZQL axial pneumatic clutch. |

ZJ series twin-shaft mixer is suitable for humidifying and stirring powdery and small granular materials. The material has low viscosity and is easy to stir.

| Model | ZJ250 | ZJ300 | ZJ400 | ZJ500 | ZJ600 | ZJ650 | ZJ700 | ZJ800 | ZJ900 |

| Blade rotation diameter(mm) | 250 | 300 | 400 | 500 | 600 | 650 | 700 | 800 | 900 |

| Rotating speed of main axes(r/min) | 62.6 | 63.5 | 53 | 53 | 53 | 53 | 45 | 45 | 45 |

| Stirring tank length(mm) | 1500-2500 | 2000-4000 | 2000-4000 | 2000-4000 | 2000-6000 | 2000-6000 | 3000-4000 | 3000-4000 | 3000-4000 |

| Distance between inlet and outlet(mm) | 900-1900 | 1400-3400 | 1300-3300 | 1300-3300 | 1200-5200 | 2200-5200 | 2200-3200 | 2200-3200 | 2200-3200 |

| Capacity(m³/h) | 0-3 | >3-6 | >6-12 | >12-25 | >25-35 | >35-45 | >45-50 | >50-70 | >70-100 |

| Motor power/kw | 7.5 | 11 | 2000≤tank length<3000 | 3000≤tank length≤4000 | 2000≤tank length<3000 | 3000≤tank length≤4000 | 2000≤tank length<3000 | 3000≤tank length≤5000 | 5000≤tank length≤6000 | 2000≤tank length<3000 | 3000≤tank length≤5000 | 5000≤tank length≤6000 | 55 | 75 | 90 |

| 15 | 18.5 | 18.5 | 22 | 30 | 37 | 45 | 37 | 45 | 55 |

Note: 1. The production capacity in the equipment table is the production capacity when the blade inclination angle is 15 degrees and the filling factor is 0.33.

2. The power in the equipment table is the power when the bulk density is 1.0-1.3.

3. This series of double-shaft mixers is equipped with ZSY series hard tooth surface reducer and YOX series hydraulic coupler.

|

Project Cases

LECA PRODUCTION LINE

LECA PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

MAGNESIUM PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

ACTIVE LIME PRODUCTION LINE

CEMENT GRINDING STATION

CEMENT GRINDING STATION

CEMENT PRODUCTION LINE

CEMENT PRODUCTION LINE

LIME SLAKING PLANT

LIME SLAKING PLANT

MAGNESIUM OXIDE (MgO) PLANT

MAGNESIUM OXIDE (MgO) PLANT

LITHIUM PRODUCTION LINE

LITHIUM PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

GYPSUM POWDER PRODUCTION LINE

ALUMINUM ASH PROCESSING SYSTEM

ALUMINUM ASH PROCESSING SYSTEM

FRACTURING PROPPANT PRODUCTION LINE

FRACTURING PROPPANT PRODUCTION LINE

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

SOLID (HAZARDOUS) WASTE INCINERATION SYSTEM

PULVERIZED COAL PREPARATION PRODUCTION LINE

PULVERIZED COAL PREPARATION PRODUCTION LINE

GGBS PRODUCTION LINE

GGBS PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

SUPERPHOSPHATE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

MOLECULAR SIEVE PRODUCTION LINE

FLUE GAS PURIFICATION SYSTEM

FLUE GAS PURIFICATION SYSTEM

FGD SYSTEM

FGD SYSTEM

SOIL REMEDIATION SYSTEM

SOIL REMEDIATION SYSTEM

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHOGYPSUM DISPOSAL PRODUCTION LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE DRESSING LINE

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS